Traditional Basketry is one of the oldest weaving techniques passed down through generations. The craft of basket weaving is sustainable and eco-friendly. Traditionally baskets were woven by hand from natural fibres, similar to the weaving of textiles. Various natural materials have been used to create baskets, for example, bark, willow rods, grass, leaves, etc. Baskets are part of the heritage of many indigenous people.

The villages of Tamil Nadu are full of Palm trees, Coconut, dates and Palmyra. Palm is the primary raw material source for preparing baskets and related products. Other raw materials like bamboo, cane, grasses, fibres and reeds are also used in making baskets, thatch, ropes, mats and many other products.

The craft of Basket Weaving with banana fibres is predominantly found in the Kanyakumari district of Tamil Nadu. In Tamil Nadu, the weavers use dried banana leaves and extracted banana stem fibres that would otherwise be burnt or left for waste after the harvesting season. Some common raw materials and tools used are banana fibre ropes, textured rubber mats, polyester ropes and water, and essential tools like scissors, measuring tape and steel wire.

Banana fibre is one of the oldest materials widely used in Asia since ancient times, as per archaeological evidence discovered. In Akhanda Bharat especially, the banana is referred to as the kalpa vriksha, with every part used for either culinary purposes or household uses or to make shelters.

Although not many people know its existence or use, banana fibre is not a recent innovation. People have been making fibres out of banana stems since the early 13th century. Banana fibres can be used to make ropes, mats, woven fabrics, and handmade papers.

Weaving Banana Fibres into Baskets and Mats

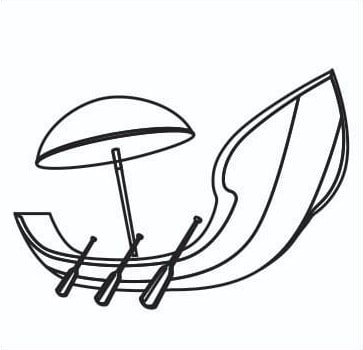

The initial process of banana fibre weaving is highly crucial. It starts with extracting the banana stem, cutting, cleaning and drying them into individual strands and later soaking them to create ropes according to the basket’s size, shape and design. The entire preparatory process helps manipulate the banana leaves during weaving.

Making rope is crucial and requires drying, peeling and soaking in water to soften the strands. Once the strands are soft enough, 2 to 3 are combined to make one single sturdy fibre. The strands are rubbed on textured rubber mats and then twisted over each other to form tighter bonds of ropes. The thickness of the fibre depends on the design of the basket. Ten barks give 80 metres of twisted rope.

These ropes can then be knitted, crocheted or woven to create a range of products from baskets to coasters to bags to mats and textiles. The fibre can also be woven on a handloom to make mats and other eco-friendly products. The variety in products requires different knitting techniques and designs to maintain the uniqueness of each product.

To weave a basket, knitting is started from the base with the help of knitting needles and steel wires. The steel wire forms the structure of the basket, and banana fibre ropes are knitted over to it. In the case of larger baskets and products, the steel wires provide the necessary strength and sturdiness, making the product durable and long-lasting.

Along with weaving, knitting is also a part of the process of banana basket weaving. The fibre rope is first woven into a flat circular or oval shape as the object’s base, after which the steel wire is directed upwards to form the ‘warp’, which is then interwoven with banana fibre ropes. The cylindrical walls are continuously aligned and measured to maintain the product’s aesthetics. Once the weaving is completed, the extra fibres are tied and cut off to maintain a clean finish.

Designing Banana Fibre hats is done by knitting over the fibre rope itself. The reference of a hat is taken to measure the size and refer to the design. The front portion of the cap, which provides shade, is completed first, followed by the headband and top part. The hat is continuously measured while knitting and watered so that the fibre ropes can be handled well. Finally, it is lightly beaten with stone in the interior section to flatten any sharp edges.

Banana fibre, also known as Musa fibre, is one of the world’s strongest natural fibres. Biodegradable, the natural fibre is made from the banana tree’s stem and is incredibly durable. The craft cluster of Tamil Nadu is known not only for the judicious use of banana fibre but also women’s empowerment. Through this initiative, we aim to reach out to the artisans and craftsmen at the grass root level. The artisans and craftsmen involved in the industry will benefit through knowledge dissemination and exposure to urban markets and design intervention, innovative designs and linkages with new markets.

With Heritage Art, embark on a journey towards sustainability and empowering artisans. The Heritage Art works directly with the artisans of Tamil Nadu to source handcrafted baskets and bags. Your kind patronage will add a smile to their face and go a long way!